Categories Manufacturing, MoldWatcher

Posted on

In the world of injection molding and die-casting, ensuring product quality and preventing costly defects are top priorities. Machine vision systems play a crucial role in achieving these goals by providing automated inspection, detecting defects, and improving overall efficiency. However, choosing the right machine vision system for your molding operation requires careful consideration of several key factors. Here’s what you need to know.

Categories MoldWatcher

Posted on

In manufacturing, downtime is more than just a temporary inconvenience—it’s a costly disruption that can significantly impact productivity, profitability, and customer satisfaction. Injection molding and die-casting operations, in particular, are vulnerable to unplanned downtime caused by mold damage, defective parts, and equipment failures. Investing in preventative vision inspection can help minimize these risks, ensuring smooth and efficient production.

Categories MoldWatcher

Posted on

Prevent Catastrophic Injection Mold Failures with MoldWatcher: The Ultimate Mold Protection Solution

In the world of injection molding, machine vision technology is transforming mold protection, ensuring efficiency, precision, and cost savings. For decades, Avalon Vision Solutions has been at the forefront of vision mold protection technology. The company’s advanced MoldWatcher™ system provides a cutting-edge solution that prevents catastrophic mold failures by leveraging non-contact vision technology. MoldWatcher™ detects potential issues before they escalate, saving manufacturers from costly repairs and unplanned downtime.

Categories Manufacturing

Posted on

Avalon Vision Solutions provides a wide range of injection mold protection solutions tailored to the needs of the injection molding and die cast industries, aimed at preventing CARs. Our flagship product, MoldWatcher, automatically inspects for insertsv

Categories Manufacturing, ThermalWatch, Uncategorized

Posted on

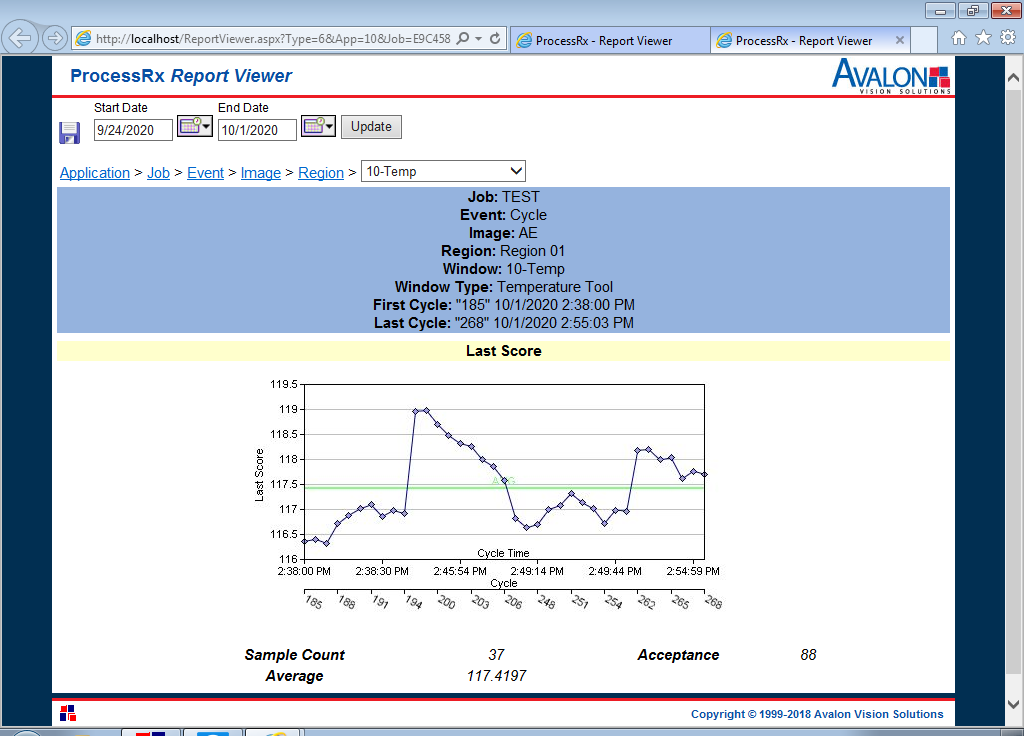

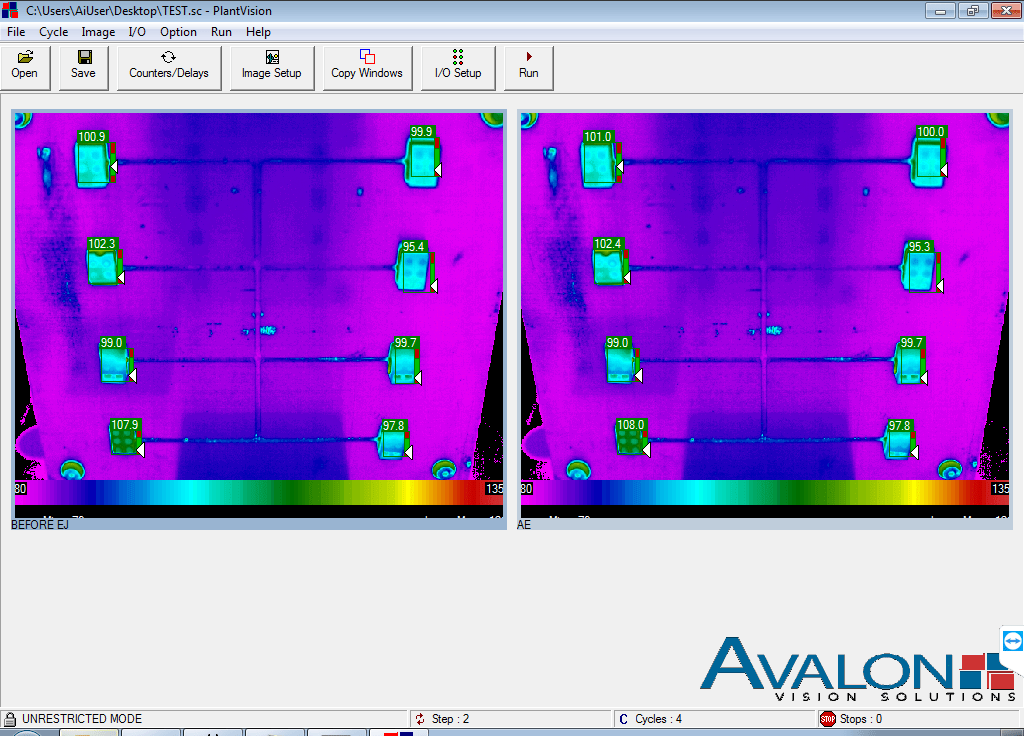

In 2022 Avalon introduced its ThermalWatch thermal imaging system to provide provide consistent, 100% cycle inspection of the thermal characteristics of molded parts and mold components. These measurements can be used to fine tune a process during startup and/or to provide continuous measurement to ensure that the process remains within specifications.

Categories MoldWatcher

Posted on

The intricate process of Metal Injection Molding (MIM) can cause broken and/or stuck parts which leads to very expensive repairs. One of Avalon Vision Solutions first customers was an MIM manufacturer, and we take pride in successfully protecting the mold to keep the MIM manufacturing process going smoothly.

Categories MoldWatcher

Posted on

Plastic parts for medical uses typically involve very detailed molds that can be easily damaged. Removal can be difficult due to tiny core pins and non-fills can occur. MoldWatcher prevents damage before it occurs and insures that manufacturing process continues running smoothly. MoldWatcher mold vision inspection in the medical plastics manufacturing sector is an essential component of the molding process.

Categories MoldWatcher

Posted on

Avalon Vision Solutions advanced mold vision protection is essential to all automotive plastic manufacturers.

Categories NightHawk

Posted on

Categories MoldWatcher

Posted on

When lifters and/or ejectors on an injection mold do not return, severe damage can occur on the mold. Traditionally, injection mold press manufacturers have tried to ease the minds of their customers, by installing pressure sensors that are intended to catch the problem. Unfortunately, pressure sensors catch the issue after they occur meaning your production must halt, deadlines may not be met, and costly repairs need to take place.

Categories NightHawk

Posted on

Avalon's MoldWatcher solution has gotten easier with the new automated camera - NightHawk. Available for injection molds and die cast machines, our new IP based automated camera touts several advanced features.

Categories Company

Posted on

Avalon Vision Solutions will be attending the K Show in Düsseldorf, Germany on October 16-23. Hall 13 B91-02.