Introduction

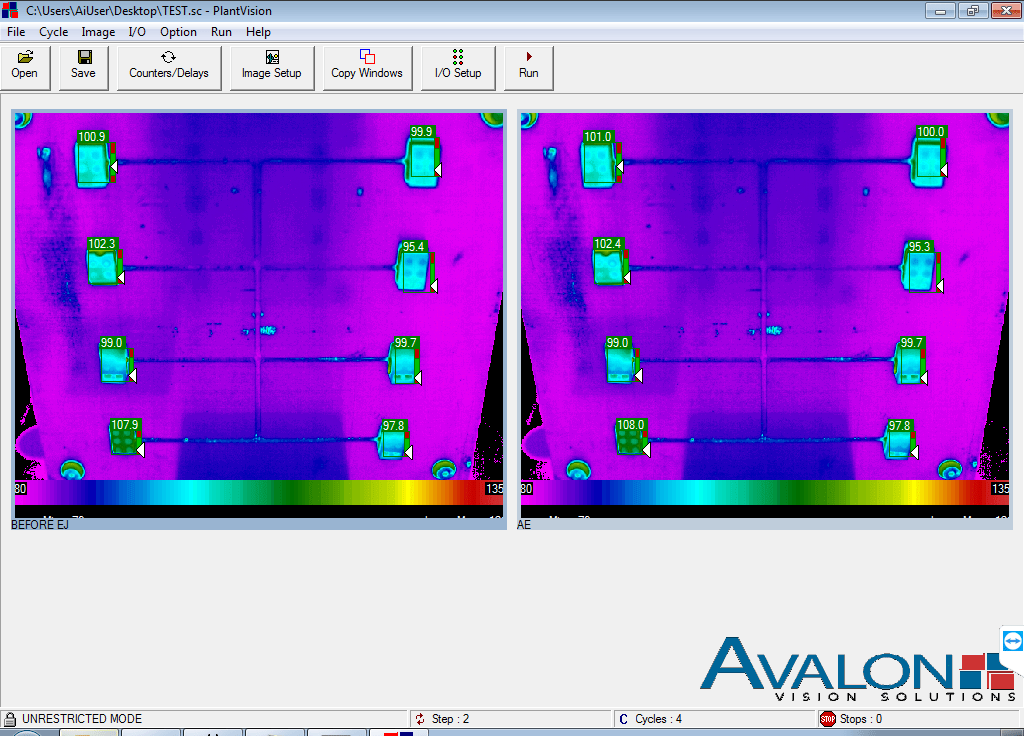

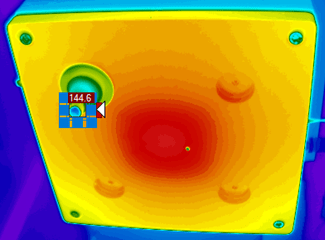

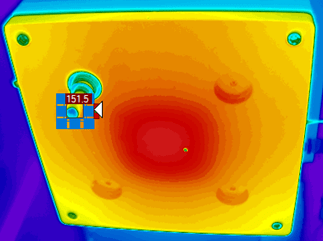

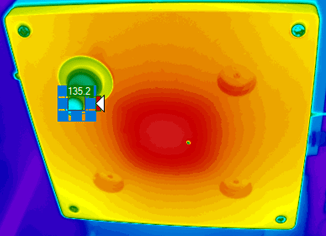

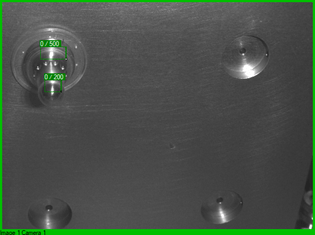

In 2022 Avalon introduced its ThermalWatch thermal imaging system to provide provide consistent, 100% cycle inspection of the thermal characteristics of molded parts and mold components. These measurements can be used to fine tune a process during startup and/or to provide continuous measurement to ensure that the process remains within specifications. An additional benefit of the ThermalWatch system is providing a more traditional mold protection capability for parts that have, in the past, been difficult to light and inspect with traditional methods, such as clear parts, like lenses, face shields, etc. Clear materials can be tricky to light and often it is the visual effects of the material on the mold that is detectable, like changes in reflected light, and not the part itself. This can cause issues due to changing conditions on the surface of the mold like buildup of material residue and mold release agents. Thermal imaging provides a means to directly inspect parts without the need for any additional lighting.

Proper lighting is one of the primary issues of concern in all vision mold protection applications. In years past, high output halogen, incandescent, and fluorescent lights were used. These lights had to be bright enough to overcome ambient light conditions in order to provide stable images and prevent lighting changes in the environment from effecting the accuracy of the vision system. These lights were often large and hot making them difficult to work around and place properly. LED lights have replaced the older lighting technologies in nearly all cases, solving many of the problems the older lighting methods presented. However, these lights still suffered when it came to ambient light conditions where environmental light sources would overpower the LED lights, such as bright flashing lights on cranes, loading equipment & alarm towers, as well overhead and ambient lighting that would change over time, like night time power saving operations, skylights and windows. More than two decades ago, Avalon, through its patented near-infrared lighting technology and process, provided a means to all but eliminate ambient light issues from vision mold protection. Today the use of thermal imaging has completely eliminated the need for lighting making the detection of previously difficult to inspect parts & materials trivial.

Conclusion

Because mold and part temperatures are different and relatively consistent over time the vision system is able to distinguish between the two and detect the presence or absence of the part in situations where near-IR or visibly light systems would have a difficult time detecting parts.