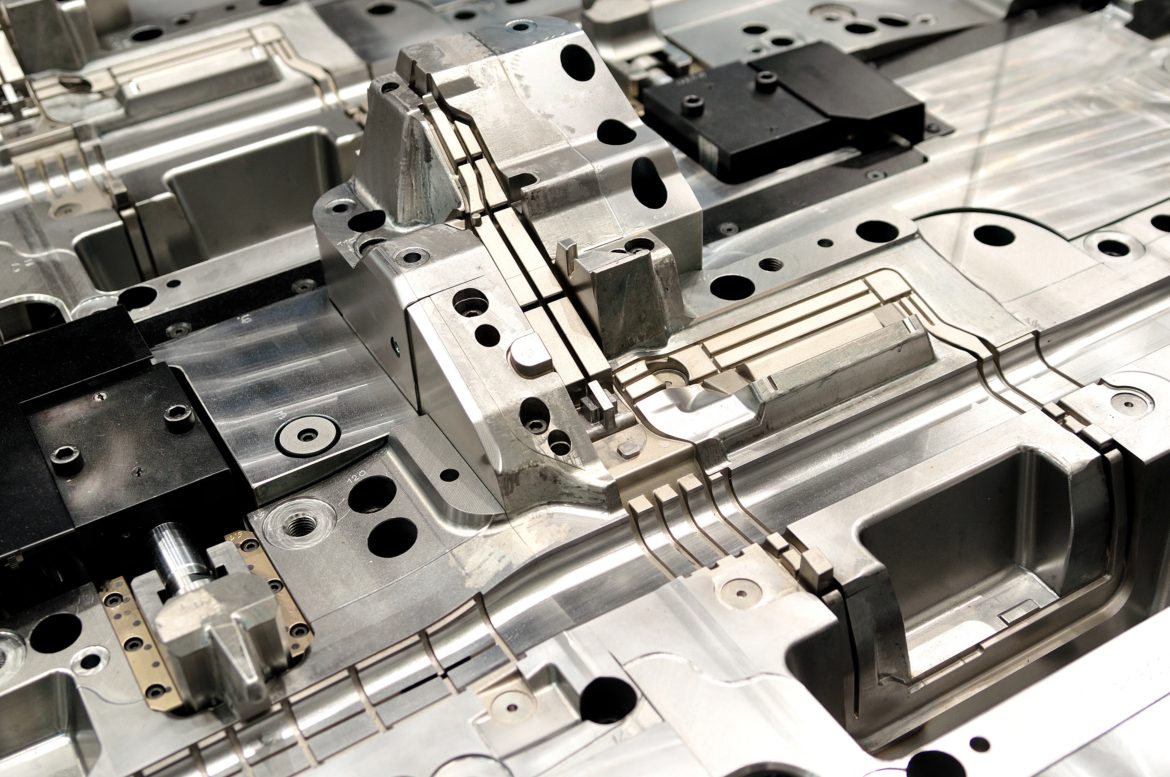

When lifters and/or ejectors on an injection mold do not return, severe damage can occur on the mold. Traditionally, injection mold press manufacturers have tried to ease the minds of their customers, by installing pressure sensors that are intended to catch the problem. Unfortunately, pressure sensors catch the issue after they occur meaning your production must halt, deadlines may not be met, and costly repairs need to take place.

What is your alternative to prevent breaking the lifters and/or ejectors?

With Avalon’s MoldWatcher solution, a snapshot of the mold is taken before and after injection to ensure the lifters and/or ejectors have returned and the mold is clear and ready for the next cycle. If MoldWatcher detects that the lifters and/or ejector has not returned, the press is stopped before any damage can occur and a red light and sound will alert the employees to the issue. This allows the issue to be assessed and fixed in a timely manner to ensure parts are shipped on time.

ProcessRx gives the added features of graphs, image stills that can be viewed as a movie, and other powerful tools that will allow the engineer to discover what led to the issue to determine the best way to prevent the error from occurring again.